Greed for profit and consumerism dominate the fashion industry. But there is a hint of hope from Switzerland, where three youngsters are predicting the future for the big names. Michael Mangold, Samuel Thoma and Nicolas Schierle produce sustainable and fair clothing for fashion labels with Labwear Studios – in a way that deserves a standing ovation.

FACES: You have taken up the cause of redesigning fashion production. An ambitious goal! How did you come up with this idea?

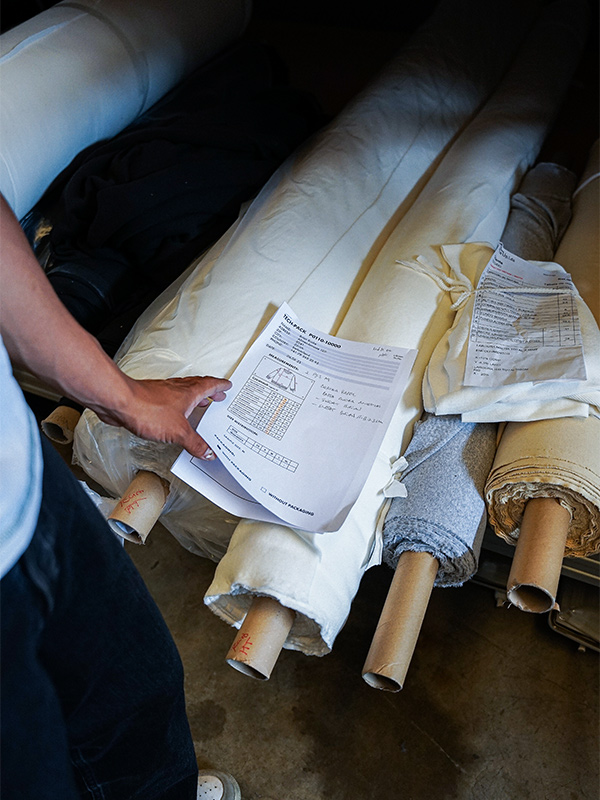

Michael Mangold, Samuel Thoma & Nicolas Schierle: We launched our own fashion brands a few years ago. Our paths crossed once and we realized that we were all facing the same problems. We didn’t manage to make the products we wanted because the quantities were always too small for production. If you want to produce fewer than 500 T-shirts, you have a hard time with the factories – sometimes we didn’t even get a response to our inquiries. This was the reason why we joined forces to produce blanks for other brands. The first batch amounted to 3,000 units, which we produced in Portugal. Since then, we have delved deep into the issue of production and have realized that the cause of the environmental problem lies in production. We have been rethinking textile production for two years now and creating new concepts that we are adapting from other industries such as automotive production.

FACES: Who all works for you guys, and how do you divide up the work?

Michael Mangold, Samuel Thoma & Nicolas Schierle: We are three co-founders. As Marketing Director, Mike is responsible for the development of the client journey and the brand. Our Creative Director Sam develops new product concepts, graphic designs and campaigns. Nicolas is the CEO and is responsible for business development, sales and operations. However, we are now a team of almost ten people who support us with content production, client service and product development. There is a lot to do.

FACES: What are your professional backgrounds?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Nicolas completed his bachelor’s degree in business administration at the beginning of the year and has been fully employed in the start-up ever since. Mike is currently studying Electrical Engineering at ETH, while Sam is completing Business Engineering at OST.

natural mono fibers.

Sustainable production and intelligent software

FACES: How exactly do you make garment production sustainable, and what software and tools do you use to do this?

Michael Mangold, Samuel Thoma & Nicolas Schierle: By generating as little waste as possible and only producing the garments that are actually in demand by consumers, instead of the usual twenty to thirty percent overproduction. In addition, all garments are recyclable as they are made from mono-fiber fabrics. Circularity and lean manufacturing are our core approaches to greater sustainability. In order to avoid as much waste as possible and only produce the garments that are in demand, we need a lot of data – from both the demand and production side. This enables us to know what is in demand and where production is located so that we can optimally coordinate the two and ensure highly efficient processes across a whole range of factories. All factories are connected to the

software and receive production orders according to the slots that are automatically allocated via the software, with live status tracking.

FACES: The production of fashion involves an incredible number of steps and details. How long did it take you to get your processes ready to go to market?

Michael Mangold, Samuel Thoma & Nicolas Schierle: When we developed our first T-shirts in Portugal, we definitely thought it would be easier. It was only then that we realized that even a seemingly simple item of clothing like a plain white T-shirt involves many individual work steps and goes through various production facilities. Over the course of several months, we have intensively examined the entire process and learned new things. This made us realize how problematic fashion production can be and that it is time to pursue new approaches. Fortunately, we have partners at our side who are open to innovation. Since the market launch, we have continued to greatly optimize our processes, and every additional garment we produce gives us an opportunity to continuously improve our processes.

Current collaborations

FACES: What fashion labels do you work with?

Michael Mangold, Samuel Thoma & Nicolas Schierle: We work with over a hundred smaller fashion labels and designers, including Yannik Zamboni’s Maison Blanche, Ilhement from Zurich and Sovereign from the USA. In the past, we have also collaborated with Vogue UA and Nike.

FACES: Where do you produce?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Around the Braga region in Portugal.

FACES: How did you finance your beginnings?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Through our own resources and loans from our families.

Nothing beats a vision

FACES: What is your vision for Labwear Studios?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Labwear Studios stands for Fashion Industry 4.0, in which we use smart ecosystems from factories to produce as circularly and locally as possible – without overproduction. There should also be full transparency regarding the footprint of the various materials and the production sites. Labwear Studios will thus become the ultimate production provider for fashion designers and brands. Everyone should have equal access to production opportunities in order to promote a culture of diversity and innovation. The goal is a fashion industry that is not driven by consumption, but by innovation, sustainability and culture.

FACES: Who do you wish you had more support from?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Compared to the USA, we are in a more conservative environment in Switzerland. Moreover, fashion is an industry dominated by large companies and mass production. These circumstances make it rather difficult for start-ups. In general, we would like to see more openness towards new innovative approaches. It would be great if people with a lot of influence in established industries in particular would make their powerful resources available for pilot tests without a start-up losing its independence.

FACES: What’s the problem with producing in Europe?

Michael Mangold, Samuel Thoma & Nicolas Schierle: The problem with production in Europe is that clothing production here is very traditional and unattractive to young people. This creates a shortage of labor and innovation in the industry. Our aim is to use our innovation to transform the industry in the direction of lean manufacturing. With this change, we want to make the market more attractive again and bring new momentum to the sector. Our focus is on bringing a breath of fresh air into traditional production and promoting innovative approaches.

Hurdles are there to be jumped over

FACES: What hurdle have you successfully overcome and what one are you facing right now?

Michael Mangold, Samuel Thoma & Nicolas Schierle: “ We have successfully built up a stable business over the past few months and are working at full capacity in one of our factories. The next hurdles are a first round of financing to scale the business.

FACES: Why don’t more companies work the way you do?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Most companies in the fashion industry are busy with their day-to-day business. The pace is very high, as is the stress level. This leaves little room for innovation and unique out-of-the-box thinking. As an industry outsider, it is easier to escape these circumstances.

FACES: What circumstance of normal fashion productions makes you most stunned and angry?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Prices are constantly being pushed down, as a result of which consumers have become accustomed to unrealistically low price levels, while the workers in the factories are paid unfairly. There is a constant urge to produce more and cheaper, but this approach is not sustainable or viable. Another worrying aspect is greenwashing. Instead of working effectively on sustainability, pseudo-sustainable products are being developed, such as a blend of 70 percent recycled cotton and 30 percent recycled polyester, which only exacerbate the industry’s waste problem.

Portuguese city of Braga.

The formula for success

FACES: What does it take to be successful in this business?

Michael Mangold, Samuel Thoma & Nicolas Schierle: On the production side, you need a deep understanding of production processes, and on the customer side, you need a good storyline to build a strong community.

FACES: What did you imagine the fashion industry used to be like, and what is it actually like?

Michael Mangold, Samuel Thoma & Nicolas Schierle: We imagined the industry to be a little more open and inclusive. Ultimately, however, it is driven by gatekeeping, competition, consumption and profit.

FACES: What do you wish you had known before you started Labwear Studios?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Sometimes it’s better to know less, otherwise you might not tackle things in the first place. A certain naivety is important for innovation.

The biggest success and the biggest fail

FACES: What’s the biggest fail and what’s the biggest success you’ve had so far?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Shortly before we started the small batch production business for brands and fashion designers, we had another pilot launch. This went completely wrong, but laid the foundation for the current business. As far as our greatest successes to date are concerned, there are two milestones to mention: firstly, the collaboration with Vogue UA at Paris Fashion Week, and secondly, the moment when our capacity was increased to the point where we could fully utilize our own factory.

FACES: How do you define sustainable clothing?

Michael Mangold, Samuel Thoma & Nicolas Schierle: As fairly produced clothing that has short transportation routes, generates minimal waste and is designed in a circular way. Above all, this means that fashion should be of high quality and durable in order to offer an upcycling opportunity. It should also be made of monofibers to enable easy recycling.

FACES: How do you go about buying clothes yourselves?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Our closets are full of Labwear, so we hardly need to buy anything anymore. When we buy something, it is often vintage or a product of the highest possible quality that will remain in our closet for a long time. We buy very consciously, not impulsively, and preferably from young fashion designers via pre-order.

FACES: What do you do with clothes that you no longer want to wear in your private life?

Michael Mangold, Samuel Thoma & Nicolas Schierle: We are happy to sew a new item of clothing from it or sell or donate it as a second-hand item. Old T-shirts, for example, can easily be converted into tank tops or cropped T-shirts at home or completely re-sewn.

Consumers tip the scales.

FACES: Consumers have little insight into the production and background of the garments they buy. How can they still contribute to making the fashion industry better?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Buy brands that are as transparent as possible, stand for good working conditions and invest in green innovation, and buy clothes consciously. Do I need another T-shirt? This question arises in particular with the numerous discount campaigns. Pre-orders are significantly better, as the T-shirt is not produced until the order is placed.

FACES: How do consumers recognize greenwashing in fashion?

Michael Mangold, Samuel Thoma & Nicolas Schierle: To recognize greenwashing in fashion, consumers should focus on the company as a whole, not just on individual products. Look for whether the company has a comprehensive approach to sustainability, such as a take-back service, monofibers in products and transparency in the supply chain. Innovation projects in the area of circularity are also a good sign of authentic sustainability. Although it can be difficult to spot greenwashing perfectly, a close examination of company practices often provides clues as to how seriously the company is actually pursuing its sustainability efforts.

This is how much a sustainably and fairly produced T-shirt costs

FACES: How much does a T-shirt have to cost to be sustainable and fairly produced?

Michael Mangold, Samuel Thoma & Nicolas Schierle: If you assume the usual margins, a sustainably and fairly produced T-shirt must cost at least 45 francs. Our customers sell the T-shirts for between 40 and 120 francs. Higher prices are important in order to build a circular economy, because the transportation costs must not be too high in relation to the product price so that brands can offer a take-back service and it is worth turning the T-shirts into a new product with upcycling instead of producing a completely new one.

FACES: Are there any fashion brands that are already doing everything right?

Michael Mangold, Samuel Thoma & Nicolas Schierle: It is unlikely that there are brands that operate perfectly in all aspects and have no room for improvement. The fashion industry is extremely complex, and even sustainable brands still have areas in which they can develop further. However, there are certainly some brands that are leading the way in terms of sustainability and social responsibility and are taking an exemplary approach. However, absolute perfection is difficult to achieve. The fashion industry is constantly changing, and it is important that brands continually strive to

to improve their sustainability efforts.

FACES: How critical are you of fashion trends, and do you even need them?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Fashion trends are important. These show what is currently culturally popular. With short-lived trends, however, it is important that these products can be upcycled and sewn into a new trendy item of clothing instead of ending up in the bin.

Portugal.

State and global restrictions and regulations

FACES: How important are government and global agreements and regulations in making fashion production more sustainable and controlled?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Very important, because the fashion industry has global supply chains and will not want to change on its own.

FACES: What other innovative ideas are there to make the production and consumption of fashion more sustainable?

Michael Mangold, Samuel Thoma & Nicolas Schierle: There are exciting ideas in the field of 3D knitwear and footwear. A 3D knit sweater comes directly from a knitting machine, without any offcuts, i.e. without waste, and can be produced at the touch of a button. The same principle applies to shoes from the 3D printer, which can be recycled back into granulate. It is fundamentally exciting when brands no longer concentrate on selling new products, but instead build communities and serve them with a circular clothing service. Consumers can therefore buy into the brand and give items of clothing for repair, upcycling or recycling, similar to what Patagonia already does.

FACES: Despite these ideas, rethinking in the industry is slow. Consumers, designers, CEOs: where is the problem?

Michael Mangold, Samuel Thoma & Nicolas Schierle: On the money. Companies want to increase their profits and consumers want to pay as little as possible for their clothes.

FACES: How do you convince big brands and companies to work with you?

Michael Mangold, Samuel Thoma & Nicolas Schierle: Our strength lies in our innovative power and in our collaboration with small designers and brands that rely on innovation in design, product, supply chain and marketing in order to survive. Our extensive knowledge of the latest trends in product development, sales and the supply chain gives us an advantage, as larger brands and companies only pick up on these trends later. Our experience in areas such as on-demand manufacturing and pre-order production makes us one of the most attractive options for larger fashion companies that will soon have to implement these trends as well.

Labwear Studios

It could be so easy to produce fashion sustainably and fairly. With Labwear Studios, the three young Swiss men Michael Mangold, Samuel Thoma and Nicolas Schierle are doing what the big names in the industry still don’t dare to do. In 2021, the three founded their company to put an end to overproduction and poor working conditions. Their goal: a circular system in which garments are always recycled. The magic formula: small minimum order quantities, production to order instead of huge stocks, the use of mono-materials to ensure a complete recycling process and local production.

More information about Labwear Studios can be found here.

Here you can find sustainable swimwear, here you can find sustainable jewelry, and in this online store you can buy sustainable fashion.

Teaser photo & photos: © Labwear Studios